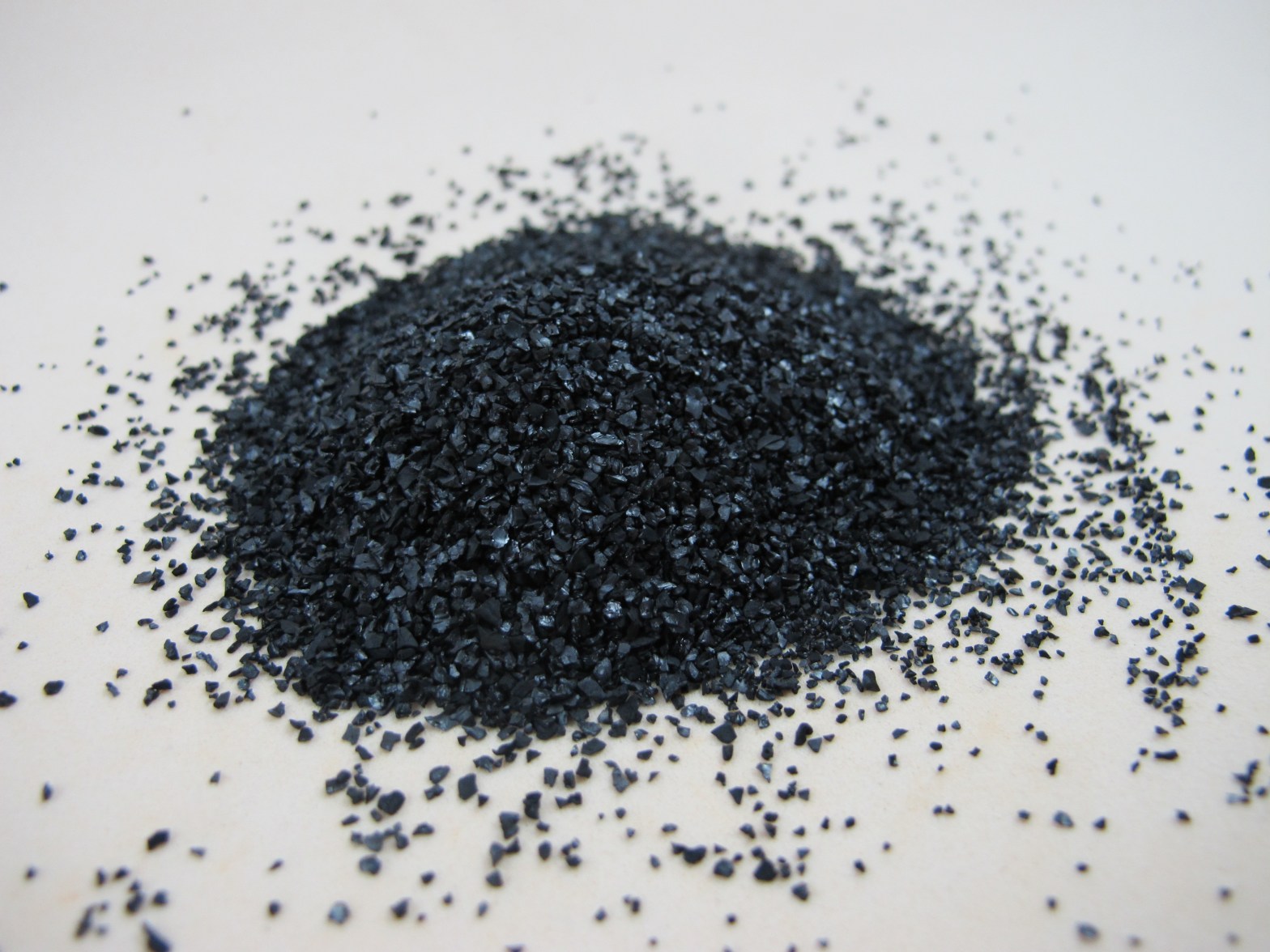

During the ordinary activity of an R/O water treatment framework, the film components will regularly endure a decrease in execution by the use of activated carbon for water treatment because of the aggregation of little particles, colloids, microorganisms, or accelerated salts gathering on the layer surface.

A portion of these stores can bring about a disastrous film disappointment in a generally brief timeframe. Pretreatment techniques, for example, cartridge filtration and synthetic pretreatment, are expected to diminish the amassing of these inconvenient stores.

The affidavit of these particles is alluded to as scaling or fouling. Mineral mixes, for example, calcium carbonate and the sulfates of barium, strontium, and calcium structure, hard glasslike encourages (scalants) by the use of activated carbon for water treatment.

How Often Should You Clean Your Membrane?

It is suggested that RO execution information be taken day by day when the framework is inactivity. From this information, one can decide when the time has come to play out a film cleaning.

The three most basic operational boundaries are differential weight, standardized saturate stream and salt dismissal. When any of these boundaries changes by 10% or more, the time has come to consider upkeep cleaning. It is generally significant, in any case, that the instruments used to quantify these boundaries be in acceptable working request and appropriately adjusted.

Kinds of Membrane Cleaners

Ordinarily, the two sorts of layer cleaners are low pH and high pH arrangements. Low pH arrangements are utilized to disintegrate layer scales, for example, calcium carbonate, calcium phosphate, iron sulfide, metal silicates, and metallic oxides. High pH cleaners are defined to clean colloids, naturally suspended issues, and organic microorganisms by the application of activated carbon for water treatment.

As can be seen, a few cleaners (low pH) are useful for dissolving scalants while others (high pH) are more successful for dissolving foulants. Mineral scale development results from mineral precipitation. Scale structures when the centralization of certain sparingly solvent constituents in the concentrate stream surpass their immersion point and hasten onto the film surface.

Accordingly, scales will in general shape in the last phases of an R/O framework where the concentrate stream is generally thought. In a two-stage R/O framework, the subsequent stage will be generally vulnerable to scaling, which will expand the second-stage differential weight. It is additionally normal to see a comparing decline in saturating creation from the influenced film components from activated carbon for water treatment.

When a fruitful cleaning method has been set up, keep on rehashing the strategy as long as great outcomes are accomplished.

Cleaning System Overview

The framework is intended to permit occasional cleaning of the RO films in a single step with the cleaning siphon equipped for cleaning every one of the seven RO pressure vessels all the while.

The RO components ought to be cleaned at the maker’s suggested pace of 40-45 GPM per vessel, and the siphon ought to be set for a limit of 45*X GPM to empower the necessary stream to be accomplished with X number of vessels working in equal.

End

During the cleaning method, the cleaning synthetics will deliver strong particles of soil, scale metal oxides, and so on from the film surface. There is a propensity for these to agglomerate into bigger particles and get gotten again, especially at the gulf end of the primary layers in the stage by the incessant use of activated carbon for water treatment.. To forestall this; a 5-micron cartridge channel is provided, which channels the feed to the RO framework during cleaning flow